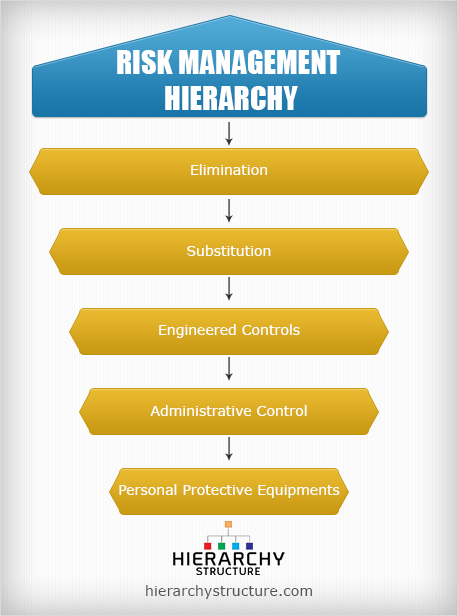

Hierarchy of risk management or hierarchy of hazard control is basically a system in few industries that works to eliminate or minimize the exposure to risks. This is a very common system that is in work in various industries and is promoted by safety organizations around the world. There are mainly five levels in the risk management hierarchy and in this article we would deal with them in the order of decreasing effectiveness.

People working in the risk management system of an organization gets recruited in one of the following levels according to their experience and qualification and gets promoted to the higher levels with time. The Risk management hierarchy or the Hazard Control hierarchy is given here in order of decreasing effectiveness as already mentioned and that is:

- Elimination

- Substitution

- Engineered controls

- Administrative control

- PPE

Elimination

This is most important and also dangerous work under the risk management hierarchy as the hazard needs to be removed physically. Workers are required to make use of proper tools and techniques in order to remove the hazard so that the rest crew can start working.

Substitution

Here, the employees are required to substitute something that is hazardous and is the second most effective hazard control. The hazardous element needs to be replaced with something that is not hazardous in nature. Like for example, replacing DDT (which is a harmful pesticide) with bio-manure or a pesticide that does not harm the environment and the product should be such that it does not produce any hazard.

Engineered Controls

This is the third most effective and useful way to control hazards and employees working under this head need to possess specific skills and these people do not really control or eliminate hazard but they prevent it from happening. They isolate people from any kind of future hazard and the capital costs involved in engineered controls are quite high though it saves a lot in the future. For example, engineered controls include building an enclosure that there is physical barrier between the hazard and the personnel so that they are not directly exposed to any kind of hazard. It might also include building a platform rather than replace or maintain fall arrest equipment. Using Fume Hood which is a ventilation device can also be used to remove contaminants that are present in the air and that are also a part of engineered controls.

Administrative Control

Administrative controls include alterations to way people work and can be associated with procedure changes, installation of warning signs and labels (like ‘Men at Work’, ‘Drive Slow’) training etc. These people also do not remove hazards and their function is limited preventing any accidents or hazards.

Personal Protective Equipments

Personal Protective Equipment or PPE involves the use of gloves, safety glasses, hard hats, respirators, safety footwear etc. to avoid any kind of hazard. This also ensures that the work is done safely. Sometimes some medical tests are required to be done to make sure that the PPE are safe to be used on a particular employee.